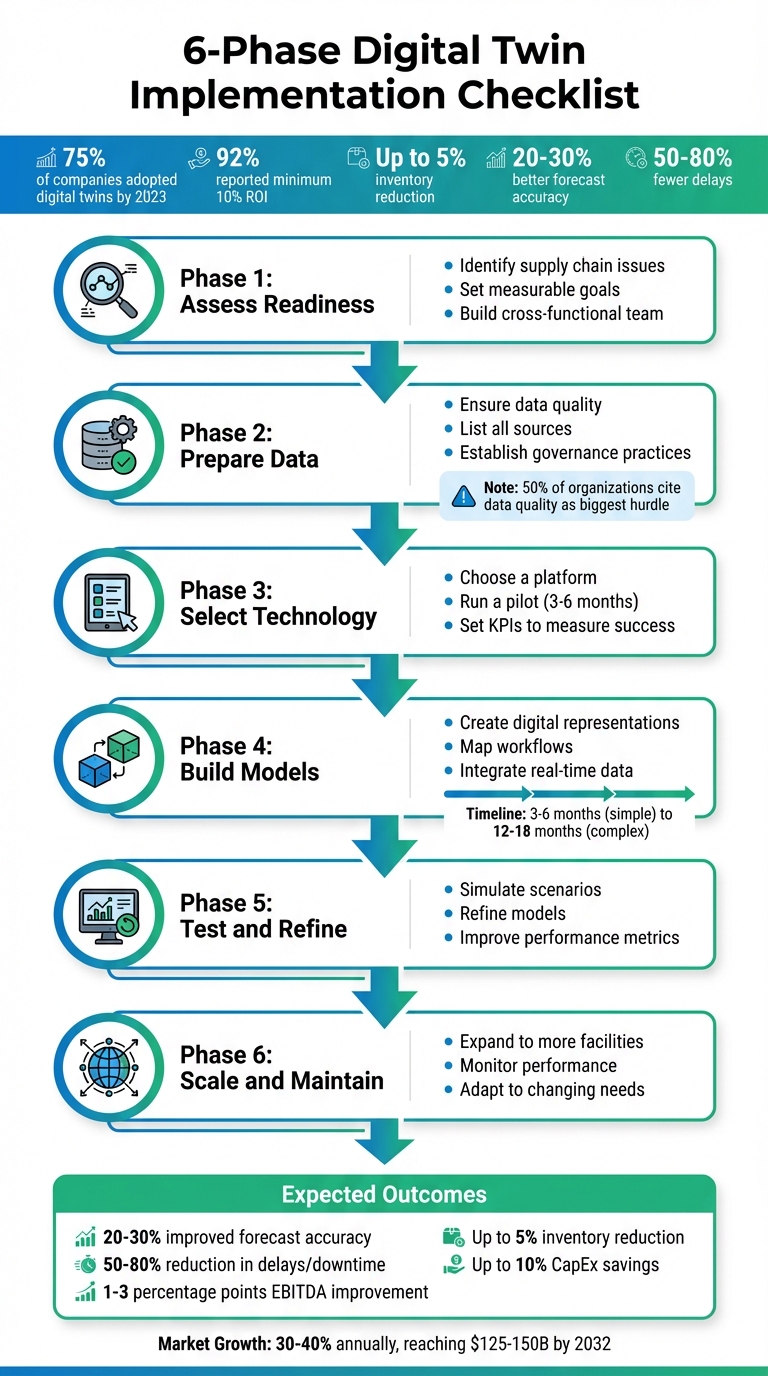

Digital twins are transforming supply chains by creating virtual models of physical systems that mirror real-time operations. These models help businesses predict disruptions, optimize processes, and improve decision-making. By 2023, 75% of companies had adopted digital twins, with 92% reporting a minimum 10% ROI. Benefits include up to 5% inventory reduction, 20%-30% better forecast accuracy, and 50%-80% fewer delays.

Here’s a 6-phase checklist to implement digital twins effectively:

- Assess Readiness: Identify supply chain issues, set measurable goals, and build a cross-functional team.

- Prepare Data: Ensure data quality, list all sources, and establish governance practices.

- Select Technology: Choose a platform, run a pilot, and set KPIs to measure success.

- Build Models: Create digital representations of assets, map workflows, and integrate real-time data.

- Test and Refine: Simulate scenarios, refine models, and improve performance metrics.

- Scale and Maintain: Expand to more facilities, monitor performance, and adapt to changing needs.

This structured approach ensures your digital twin delivers measurable improvements and positions your supply chain for long-term success.

6-Phase Digital Twin Implementation Checklist for Supply Chains

Phase 1: Assess Your Organization’s Readiness

Identify Key Supply Chain Problems

Start by identifying the major pain points in your supply chain. Common challenges include data silos, reactive crisis management, and manual processes that drain time and reduce efficiency. These issues often create bottlenecks that slow down productivity.

Focus on areas prone to high volatility, such as demand shifts, production changes, supply delays, or unexpected disruptions like port blockages or geopolitical events. Digital twins are particularly effective in these scenarios. They can simulate complex interactions across thousands of assets, warehouses, and logistics flows, uncovering hidden inefficiencies that traditional systems might overlook. For instance, if inventory mismanagement is a recurring problem – whether due to overstocking or frequent stockouts – digital twins can help strike the right balance between supply and demand.

Once you’ve pinpointed these challenges, set clear and measurable goals to tackle them.

Define Clear Business Goals

Establish specific targets that align with your planning timelines. For the short term, aim to reduce idle time for assets and anticipate potential risks. Medium-term objectives might include syncing maintenance schedules and inventory levels with demand forecasts. For the long term, focus on optimizing capital investments and rethinking your supply chain network.

"Aligning stakeholders on a clear vision of digital twins is a crucial first step." – McKinsey

Set key performance indicators (KPIs) to monitor progress. Examples include minimum stock level thresholds, acceptable delivery delays, or on-time delivery rates. These KPIs can also trigger automated alerts, enabling proactive decision-making to address issues before they escalate. A pilot project that delivers results within three to six months can be an excellent way to demonstrate the value of digital twins and build stakeholder confidence for broader implementation.

With well-defined goals in place, the next step is assembling the right team to lead the initiative.

Build a Cross-Functional Team

Create a team that spans multiple departments, including IT, operations, logistics, analytics, procurement, and finance. Each team member plays a critical role in ensuring the success of the digital twin initiative. For example:

- Data engineers ensure data quality and integration from various sources.

- Data scientists develop predictive models and identify initial use cases.

- Domain experts bring deep knowledge of your supply chain’s unique challenges and constraints.

This collaborative approach bridges technical expertise with practical insights, ensuring that your digital twin reflects the realities of your operations. By combining these perspectives, your team will be better equipped to handle the complexities of implementation and deliver meaningful results.

How to Revolutionize Your Supply Chain with Digital Twins

Phase 2: Prepare and Integrate Your Data

To make digital twins work effectively, you need clean, reliable, and well-organized data. It’s no surprise that almost 50% of organizations cite data quality and integration challenges as the biggest hurdles to success. Before diving into building your model, take the time to assess your data – what you have, where it’s stored, and how trustworthy it is.

List All Data Sources

Start by identifying and documenting all systems and devices that produce data relevant to your supply chain. Internal systems are the backbone of your data setup. For instance:

- ERP systems store financial records, maintenance logs, and procurement data.

- MES and SCADA platforms provide production control information.

- PLM systems offer engineering and design data.

On the physical side, IoT sensors track real-time metrics like temperature, pressure, and vibration. RFID scanners help manage inventory movement, while GPS-equipped trucks supply vehicle telemetry. Don’t forget external data sources, such as logistics partner updates, supplier purchase orders, and even weather or port traffic data.

Make a clear distinction between data sources that require real-time integration and those suited for batch processing. For example, a single wind turbine can generate over 5 GB of data per day. Understanding the scale and speed of these data streams is critical when designing your infrastructure.

Check Data Quality and Accuracy

Ensuring your data is accurate, complete, and up-to-date is non-negotiable. Poor data quality can cost businesses an average of $12.9 million per year. To avoid this, use Master Data Management (MDM) to create "golden records" – a single, consistent source of truth for your data.

Take Siemens’ Amberg Electronics Plant as an example. With data flowing from over 30,000 control points, they’ve achieved an impressive 99.99885% quality rate, boosting productivity eightfold over 25 years. This level of success requires rigorous data validation.

Leverage AI tools to automate quality checks, flagging issues like anomalies, sensor drift, missing data, and mismatched schemas. Set up validation rules for each data source to catch problems as they happen, rather than during analysis.

Set Up Data Governance Practices

Without strong governance, digital twin projects are prone to failure – 70% of them encounter major issues due to poor data management. Define clear ownership for every dataset, establish access controls, and set quality standards to keep things running smoothly.

Consider adopting a data mesh architecture, which gives departments control over their own data while ensuring it’s accessible for the digital twin. This approach supports real-time, domain-specific data products. Instead of exposing raw tables or APIs to AI systems, use semantic layers for added security and automatic updates.

Automate data pipelines to link cloud-based analytics platforms with legacy IT systems. Bridging the gap between industrial Operational Technology (OT) and enterprise Information Technology (IT) systems is vital, and unified data management platforms can make this easier. Documenting the flow of data – from sensors to analytics – will also help with compliance and scalability.

Once your data is organized and governed, you’ll be ready to move on to selecting the right technology and piloting your digital twin.

Phase 3: Select Technology and Run a Pilot

Now that your data is organized and governed, it’s time to choose the right technology and test it through a pilot program. This step is about making smart platform decisions and quickly demonstrating value – without overhauling your entire operation.

Choose Your Technology Platform

Pick a platform that can handle real-time data integration from multiple sources, such as ERP systems, IoT sensors, vehicle telemetry, and third-party feeds. It should consolidate this data into one easily queryable layer. Look for tools with simulation and "what-if" capabilities, which allow you to model disruptions like port delays or supply shortages and assess potential impacts before they occur.

Opt for a modular, technology-agnostic system that works seamlessly with your existing platforms – whether you’re running SAP or using cloud-based environments – so you don’t have to start from scratch. Platforms with standard SQL or user-friendly interfaces are ideal because they make it easier for business teams to adjust KPIs without needing advanced programming skills.

Begin with a small-scale implementation, such as a single facility or process, and expand as you see results. Early adopters have reported 20% to 30% improvements in forecast accuracy and 50% to 80% reductions in supply chain delays and downtime. Some have even achieved EBITDA improvements of 1 to 3 percentage points. Beyond monitoring, ensure your platform supports decision automation, such as triggering alerts or dynamic re-routing based on real-time data thresholds. Once you’ve chosen your platform, move forward with a focused pilot project.

Design a Pilot Project

With your platform in place, test your approach through a well-designed pilot. Develop a Minimum Viable Product (MVP) within three to six months, focusing on one or two high-value use cases rather than attempting a full-scale rollout right away. Keep the scope manageable – targeting a single warehouse, production line, or logistics route – to showcase value before scaling.

For example, in 2024, a steel manufacturer piloted a digital twin that allowed them to anticipate risks 12 weeks in advance, leading to a 2-percentage-point improvement in EBITDA and a 15% reduction in inventory levels. Similarly, in July 2024, a global OEM used a digital twin to optimize outbound logistics policies within its Transportation Management System (TMS), cutting freight and damage costs by 8%.

Work closely with operational staff during the pilot to ensure the digital twin delivers actionable insights in real-world scenarios. Use their feedback to identify any issues, refine your logic, and add more data sources before expanding the implementation to other areas.

Set Key Performance Indicators (KPIs)

Clear metrics are essential for evaluating your pilot’s success. Focus on financial KPIs like EBITDA improvements, reduced capital expenditures, and cost savings in procurement and labor. Track operational efficiency metrics, such as improvements in forecast accuracy, shorter planning cycles, and better asset utilization. For supply chain resilience, monitor reductions in delays, downtime, and lead times for identifying bottlenecks. On the inventory side, measure decreases in inventory levels and optimized safety stock targets.

Customer service metrics also matter. Keep an eye on on-time delivery rates and your ability to meet delivery commitments.

Establish operational triggers – specific thresholds like inventory dropping below reorder points – to turn passive monitoring into actionable insights. Companies using digital twins have reported 10% reductions in labor costs, 5% revenue increases, and 50% reductions in planning cycle times. These measurable outcomes will help you demonstrate value and secure support for scaling the initiative further.

sbb-itb-b840488

Phase 4: Build and Configure the Digital Twin

With your pilot tested and your KPIs in place, it’s time to construct the actual digital twin. This step involves creating virtual versions of your physical assets, mapping how materials and information flow through your operations, and integrating live data streams to keep everything in sync.

Create Digital Models

Start by identifying and mapping all physical assets – this includes equipment, sensors, storage areas, and even environmental factors like temperature or humidity that impact your operations. Build physics-based models that accurately represent how components interact and their constraints. For example, if you’re modeling a warehouse, you’ll need to account for storage capacity, throughput rates, and the capabilities of your handling equipment.

The timeline for building a digital twin varies. A simple model can take three to six months, while more complex setups, like production lines, may need 12 to 18 months for full deployment. It’s smart to start small – focus on a single piece of equipment or a single production line to demonstrate value quickly, then expand from there.

Before diving into the modeling, ensure your data – whether structured or unstructured – is cleaned and prepared for use. Your digital twin requires end-to-end connectivity, linking internal processes like procurement, production, and logistics with external partners such as suppliers and distributors. Once the models are complete, document how goods and data move through your system to finalize the integration.

Map Workflows and Inventory Movement

To replicate your supply chain effectively, integrate data from all sources into a single, unified view. This step ensures your digital twin mirrors actual business processes rather than just presenting raw data. It should naturally fit into your existing workflows and support collaborative efforts.

Mapping workflows also helps you anticipate risks in your supply chain weeks ahead of time. This allows teams to act proactively, implementing alternative strategies that streamline operations and lower inventory levels.

Connect tools like warehouse management systems (WMS), transportation management systems (TMS), and manufacturing execution systems (MES). By doing so, you eliminate data silos and achieve full visibility into how inventory moves – from suppliers, through production, to customers.

Connect Real-Time Data Feeds

Once your models are built and workflows mapped, it’s time to integrate live data. This ensures your digital twin stays aligned with real-world operations. Using the groundwork from earlier phases, create a unified data layer that combines ERP, GPS, sensor, and partner data. Modern streaming platforms with SQL support can simplify this process, allowing you to define real-time views without the need for overly complex custom frameworks.

Here’s an example: A mid-sized electronics manufacturer linked live data from supplier purchase orders, logistics updates, and warehouse sensors. When customs delays affected shipments, the digital twin recalculated arrival times and alerted the procurement team to source components from local vendors, avoiding stockouts. Similarly, a global logistics company managing hundreds of vehicles used GPS data and warehouse sensors to monitor operations. If a vehicle strayed from its route, the system suggested re-routing options and updated delivery estimates for customers instantly.

Adjust refresh rates based on your needs. For critical systems, updates might need to happen in milliseconds, while inventory tracking could work with minute-by-minute updates. Automate data pipelines to link sensors directly to your platform, and set up alert thresholds – for instance, notifications when inventory drops below reorder levels – to flag issues automatically. Incorporate external data, like port activity or shipping volumes, to improve forecasting accuracy. To handle data delays, implement buffer systems and clear indicators so users know when information is outdated or incomplete.

Phase 5: Test, Refine, and Improve

Now that your digital twin is connected to live data, it’s time to put it through its paces. This phase is all about stress-testing the system through simulations to identify weaknesses and fine-tune its performance before rolling it out fully. Using insights from earlier pilots, this step ensures your digital twin can deliver reliable and actionable results. Simulating potential disruptions will help uncover vulnerabilities and prepare your system for real-world challenges.

Run Scenario Simulations

Testing your digital twin under different scenarios is crucial. Simulate events like supplier shutdowns, unexpected demand surges, port delays, or blocked shipping routes to see how the system performs under stress. For instance, imagine your primary supplier goes offline for two weeks, or customer demand doubles overnight. These simulations help determine whether your digital twin can predict problems and offer actionable solutions before they escalate.

Here’s a real-world example: A pharmaceutical company tested its supply chain for injectable products by simulating a major distribution center disruption. Initially, their fixed replenishment policy caused service levels to drop to 85.6%. By experimenting with alternative inventory strategies through the digital twin, they restored service levels to 100% and aligned lead times with customer needs.

During testing, set up operational triggers like inventory thresholds, delivery metrics, and bottleneck indicators. These triggers turn passive monitoring into actionable alerts. Try out different strategies – compare minimum-maximum inventory policies with fixed replenishment to see which performs better under stress. Engage frontline staff to review simulation results and ensure the recommendations are practical for day-to-day operations.

Refine Models Based on Results

Once you’ve run simulations, use the results to refine your digital twin. Testing often uncovers hidden bottlenecks or risks that weren’t apparent during the initial design. For example, if your simulation predicted a two-day delay but the actual delay was four days, dig deeper. Perhaps customs processing times were underestimated, or weekend closures at distribution centers weren’t factored in.

Consider this: A global OEM used simulation feedback to adjust its logistics policies, cutting freight and damage-related costs by 8%. Similarly, a retailer testing a new cross-dock facility design discovered that, while initial analysis suggested a specific facility size, the digital twin showed the operation could function with 50% less space. This led to a 10% boost in regional distribution center utilization and a 5% drop in fulfillment costs.

Start with a basic version of your model and enhance it over time, ideally within three to six months, using feedback from these tests. Don’t wait for perfect data – begin with what you have and let early use cases generate the insights needed for refinement. Over time, your digital twin will evolve, running countless scenarios and learning from outcomes.

Improve Performance Metrics

Testing insights should drive improvements in efficiency, cost management, and decision-making. Companies adopting digital twins have reported 20% to 30% better forecast accuracy and 50% to 80% reductions in delays and downtime. These aren’t just goals – they’re measurable benchmarks you should aim for as you refine your system.

Track metrics like TTR (Time to Recovery) and TTS (Time to Survive) to gauge how quickly your operations bounce back from disruptions. Compare real-time data with planning data to measure forecast accuracy and identify deviations. Use tools like heatmaps to quickly spot patterns in supplier performance.

Danone Nutricia implemented digital twin technology at its Haps, Netherlands facility, cutting in-person site visits by 50% and saving hundreds of employee hours each year. Led by digital innovation manager Stuart Grace, the project enabled virtual factory tours and shortened project timelines by weeks.

In another case, a renewable energy company optimized supply chain buffers using a digital twin, reducing project delays and controlling cost overruns for a major capital project.

As you refine your system, evaluate trade-offs between cost, inventory, risk, and environmental impact. Automate alerts to notify you when key variables, like material flows or demand fluctuations, exceed safe thresholds. The ultimate goal is to shift from reacting to problems to proactively managing them with data-driven insights. With a polished model and clear performance gains, your digital twin will be ready for full-scale implementation.

Phase 6: Scale and Maintain the Digital Twin

After completing a successful pilot and thorough testing, it’s time to scale your digital twin for long-term value. This phase focuses on rolling out the solution strategically, monitoring its performance, and adapting it to meet evolving business needs. The global digital twin market is expected to grow by 30% to 40% annually, reaching $125 billion to $150 billion by 2032.

Expand to More Facilities and Functions

Start by creating a "North Star" roadmap that outlines expansion priorities based on their financial impact and technical feasibility. This roadmap ensures a structured rollout, building on the success of earlier phases. Instead of attempting a full-scale deployment immediately, take an incremental approach. For example, many companies begin by using digital twins for specific processes, like improving production line uptime or streamlining warehouse operations. Once these applications demonstrate value, the rollout can extend to broader areas, such as regional distribution centers or sourcing networks.

To support this scaling, use a modular, technology-agnostic architecture that allows for gradual capability expansion. Strong data governance is essential at this stage to maintain the quality and consistency of data from diverse sources. Scaling effectively enables businesses to achieve ongoing improvements in operations and cost efficiency through better resource planning.

As you expand, move from basic asset modeling to advanced simulations and AI-driven prescriptive analytics. This shift allows you to optimize processes in virtual environments before making changes to their physical counterparts, encouraging a digital-first mindset.

Set Up Continuous Monitoring

Once the digital twin is scaled, continuous monitoring ensures it remains aligned with real-time operations. This transforms the twin into a dynamic model capable of self-adjusting to supply chain changes. Predictive AI can offer recommendations or even automate responses to disruptions. By integrating live data feeds from IoT sensors, GPS trackers, and ERP systems, you can ensure the twin reflects the current state of operations.

Real-time synchronization enables smarter decision-making, such as adjusting SKU-level safety stock targets to match localized or seasonal demand. Monitor performance against benchmarks set during testing. Early adopters of advanced digital twins have seen impressive results, including 20% to 30% improvements in forecast accuracy and 50% to 80% reductions in delays and downtime. Use scenario modeling for "what-if" analyses, like assessing the impact of supplier outages or demand surges, to ensure the digital twin adapts to evolving business goals.

Adjust to Changing Business Needs

To remain effective, your digital twin must evolve with your business. It allows for a shift from traditional, heuristic-based supply chain management to more dynamic, detailed optimization. This provides a clearer view of performance gaps and areas for improvement. Regular updates and fine-tuning are necessary to align the twin with changing business objectives and real-world supply chain dynamics.

Adopt an agile approach, starting with a Minimum Viable Product and refining it through iterative updates. Your team should include product managers, data scientists, and UX designers skilled in agile methods to ensure rapid development cycles. Position the digital twin as an enhancement layer over existing tools like WMS or TMS. This allows it to optimize data inputs and provide predictive insights without disrupting core operations.

As your processes and technologies evolve, prioritize intuitive user interfaces to encourage consistent adoption. Companies using digital twins for managing variable demand and labor have cut total distribution center costs by 15%. Meanwhile, advanced decision-support capabilities have delivered 3% to 6% cost savings in mature procurement functions. Regular updates, combined with user feedback, will ensure the digital twin stays aligned with operational needs and business goals.

Conclusion

Implementing digital twins takes thoughtful planning, teamwork, and consistent updates. By following the six phases in this checklist – from evaluating your organization’s readiness to scaling and maintaining the system – you can shift your supply chain from reacting to problems to anticipating and addressing them. This structured approach opens the door to ongoing progress.

"Success requires starting small, iterating with real operational needs, and scaling as business value is demonstrated".

Starting with a pilot project is an effective way to prove the concept before committing to a full-scale rollout. After that, ongoing monitoring and regular updates ensure your digital twin remains aligned with your business goals and market dynamics.

The benefits are undeniable. Companies using digital twins have reported 20% to 30% better forecast accuracy, 50% to 80% fewer delays and downtime, EBITDA gains of 1 to 3 percentage points, inventory reductions of up to 5%, and capital expenditure savings of up to 10%. Beyond the numbers, digital twins provide end-to-end visibility, connecting isolated data sources and enabling faster, smarter decisions across your supply chain.

Digital twins have become a core tool for modern operations. With the global digital twin market expected to grow by 30% to 40% annually, organizations that act now will position themselves for a clear competitive edge.

"Digital twins allow companies to replace crisis management with mitigation actions".

As highlighted in the checklist, successful implementation is an ongoing process. It depends on maintaining data quality, fostering collaboration across teams, and committing to continual improvement. By keeping these priorities in focus, you’ll create a supply chain that’s not only resilient but also ready to adapt to future challenges.

FAQs

What challenges do businesses face when preparing data for digital twins in supply chains?

Getting data ready for digital twins in supply chains comes with a set of challenges that can’t be ignored. One of the most pressing issues is ensuring data quality. For digital twins to provide reliable simulations and insights, the data feeding them needs to be accurate, complete, and consistent. If the data is flawed, the digital twin’s usefulness in decision-making takes a hit.

Another significant challenge is integrating data from multiple sources throughout the supply chain. Businesses often rely on a mix of systems like CRM, ERP, and IoT devices, each with its own formats and standards. Merging this data into a single, cohesive architecture that can handle real-time updates and high volumes of information isn’t a simple task.

Finally, keeping data accurate and timely is crucial. Supply chains are constantly shifting, with disruptions like shipping delays or sudden demand spikes requiring immediate updates. Without real-time data, digital twins can quickly become outdated, reducing their effectiveness in managing operations or responding to changes.

Overcoming these challenges is key to improving visibility, streamlining operations, and making supply chains more adaptable to change.

How do digital twins help predict and manage disruptions in the supply chain?

Digital twins act as virtual models of your supply chain, giving you real-time insights into how it operates. By simulating scenarios and analyzing data, they can pinpoint potential bottlenecks, risks, or disruptions well ahead of time – sometimes even weeks in advance. This early warning system helps businesses tackle issues before they grow into larger problems.

Beyond just identifying problems, digital twins allow companies to experiment with different strategies, fine-tune processes, and make more informed decisions. This approach leads to a supply chain that’s not only more adaptable but also better equipped to minimize downtime and boost overall efficiency.

What are the key steps to successfully scale and maintain digital twins in supply chains?

To effectively scale and manage digital twins in supply chains, it’s crucial to start with a well-defined strategic plan. This plan should clearly articulate your vision, identify the types of digital twins you aim to create, and prioritize their rollout. It’s also essential to establish clear ownership and governance structures from the outset. This approach helps align all stakeholders and avoids the pitfall of creating isolated, single-purpose twins that offer limited benefits.

The next step is to build your first digital twin, a process that usually takes about three to six months. During this phase, the focus should be on collecting and refining essential data, creating visual representations, and developing initial use cases to begin generating insights. Don’t worry about achieving perfection right away – an iterative approach with room for ongoing improvement is far more effective. As time goes on, you can expand the twin’s capabilities by incorporating additional data, more advanced analytics, and new use cases to address the ever-changing demands of supply chains.

For long-term success, consistent upkeep is non-negotiable. Data models need to be regularly updated to reflect changes in the real world, and performance should be closely monitored. Strong governance structures are essential for enabling continuous optimization. Scaling digital twins effectively also requires collaboration across teams and a commitment to embedding them into broader supply chain strategies, ensuring they deliver lasting value.